・SH TRC Coating (APS)-1

・SH TRC Coating (APS)-2

・SH TRC Coating (APS)-3

・RS/PS Treatment

SH TRC Coating (APS) – 2

SH TRC Coating (APS) – 2

1st Gen. Plasma Spray Coating (Y2O3 / Al2O3)

2nd Gen. Special Material Coating (UC / BONO / Silicon)

– Reduced Porosity and micro crack inside the coating layer → better plasma & chemical resistance

– Higher Surface Roughness (Ra) compared to Y2O3 coating layer → Hold up more particle

– Minimize gas residue trapped inside the pore in coating layer

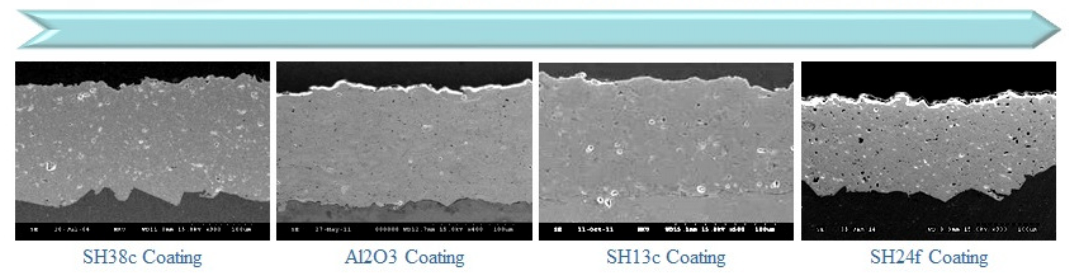

3rd Gen. TRC Coating : High Temp Coating (SH13c.f, SH24f, SH38c)

– Stable to high-temp process more than 1200℃

– Surface reaction resistance & control Metal, carbides & compound materials

– Reduced porosity and micro crack inside the coating layer

– Particle and defect control from parts surface

– Excellent plasma, chemical resistance Surface corrosion, Erosion & Oxidation protection